Saparua: plastic processing & recycling for a small island community

2022 – 2023

Transforming plastic waste into useful tools to be used.

motivation and stakeholders behind the project

Waste management on islands such as Saparua has been a substantial challenge. Due to a lack of recycling mechanisms, their waste and other objects are dumped in the sea, leading to pollution. Moreover, there is no solid system in place to manage all locally produced waste. The people of Saparua have been trying to improve their island’s waste management by increasing the reuse of plastic waste by obtaining new processing methods that will allow them to broaden their focus from collecting and gathering waste to also sorting and processing it. They aimed to make diverse items other than plastic pellets so that they could be used for agriculture, farming, and fishing purposes.

With The Constellation’s support, the people of Saparua have begun tackling this issue by devising a waste management system for the island. However, the system was only able to collect 33% of the island’s total waste. They also cannot fully complete the recycling process as they do not have the adequate machinery or the technological capabilities. They did have the basic equipment that can be used to process plastic, but this was limited to only being able to create plastic pellets. Hence, this project, aiming to design a low-cost and easy-to-use PET blow molding machine, was developed.

innovation cycle

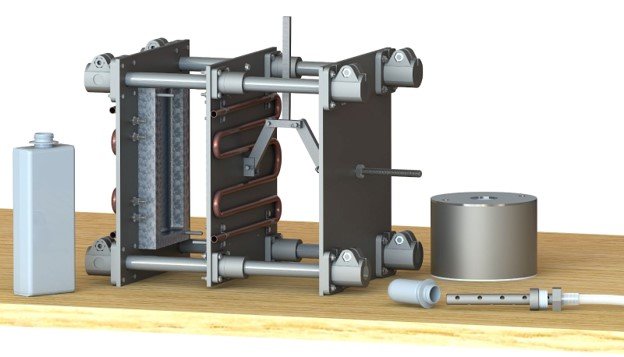

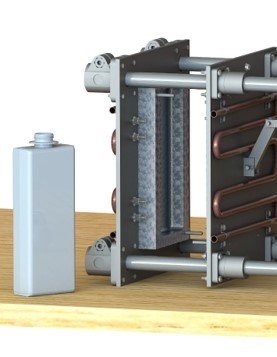

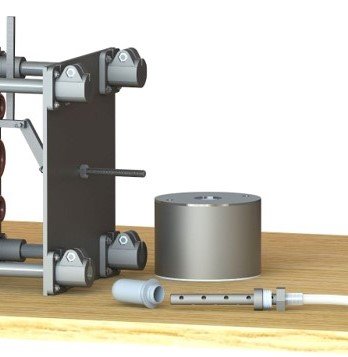

The project was adopted into the Mechanical Engineering Department of Imperial College and was taken by a student. After several meetings and discussions, the team in Saparua chose this final product to be an ice pack. A pellet maker, which already existed on the island, was used as the base to develop the preform that was required to form the ice pack.

A system to control the temperature of the system while being easy to handle, was developed. While the old pellet maker only allowed the local community to create solid products, the newly-developed molder allowed them to crease hollow products by blowing air into solid, plastic preform.

student feedback

The quality of the brief and support I got was good enough to start the project. Yet, the timeframe was slightly tight and limited me to do a prototype in the UK, which would have been a key advantage in checking feasibility. On a technical level, the project was not that complicated. What makes it interesting is the challenge to reduce the industrial process to a simpler one that can be applied in Saparua.

Working on this project has inspired me to pay attention to simplifying industrial machines and processes and making them more accessible or usable for home use to create a social impact. Moreover, this project has confirmed my interest in recycling technologies. This inspired me to learn more about making this an open source process and more available widely.

contact the team

target Location

Saparua, Moluccan Province, Indonesia

the inaglobers: Diederik evanson

The project was taken by a student from Imperial College London (Diederik Evanson), who worked together with the Sapura community.